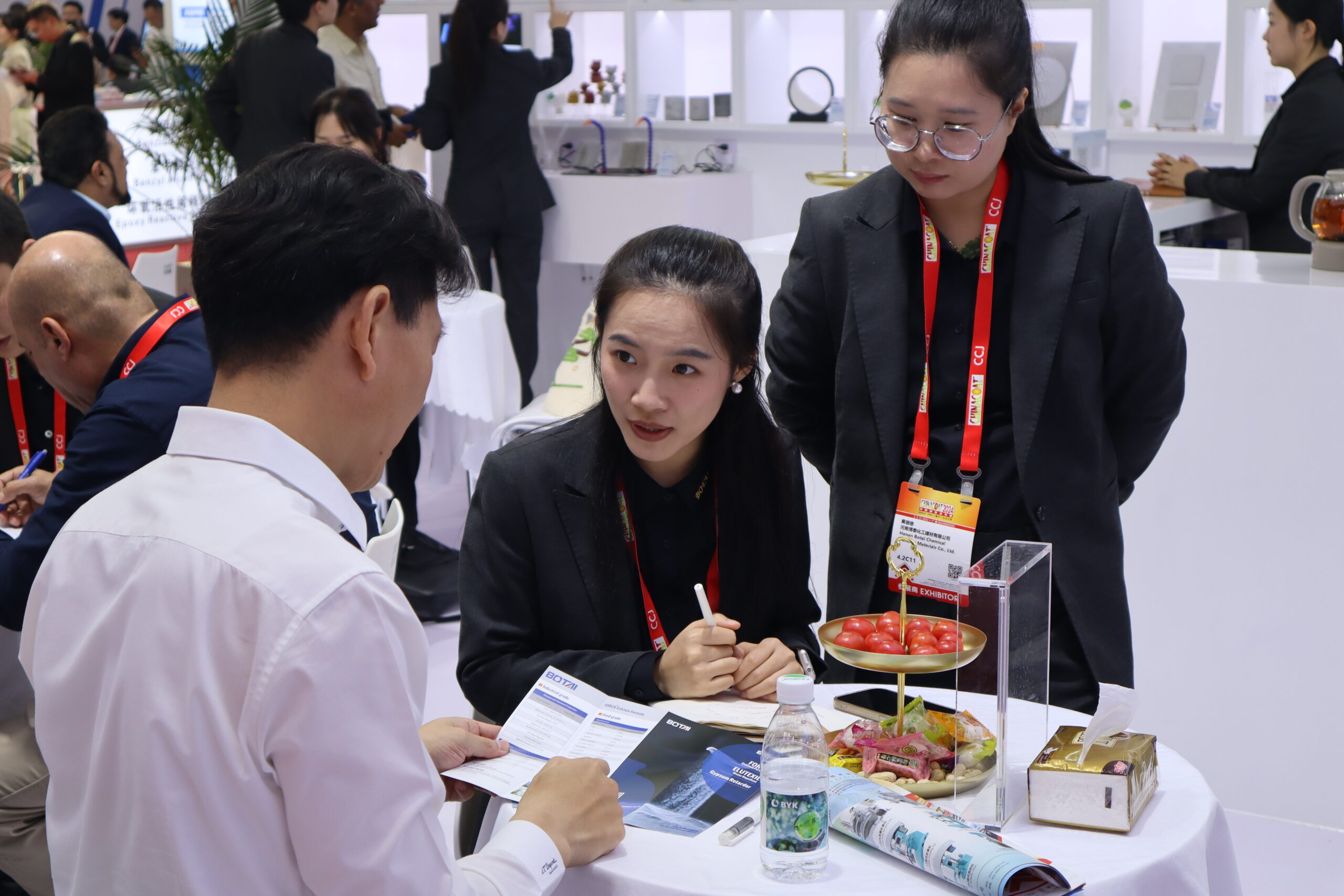

BOTAI HPMC is a non-ionic cellulose ether derived from alkali cellulose reacted with propylene oxide and methyl chloride. It offers exceptional thickening, water retention, and thermal gelation properties. Widely used in construction materials (e.g., tile adhesives, mortars), pharmaceuticals (tablet coatings), and personal care products, it ensures enhanced workability, extended open time, and controlled setting.