Here’s a professional technical guide for selecting cellulose ethers from Botai Chemical’s portfolio for putty powder formulations, with comparative analysis and application-specific recommendations:

Technical Selection Guide: Botai Cellulose Ethers for Putty Powders

Comparative Properties & Optimal Applications

| Property | VAMCELL® HPMC | HEMC/MHEC | HEC |

|---|---|---|---|

| Water Retention (%) | ≥96 (ASTM C1506) | ≥95 | 90-93 |

| Thermal Stability | Gel point: 65-85°C | Gel point: 60-75°C | Gel point: <60°C |

| Ion Tolerance | Moderate | Excellent (high salt/formula) | Poor |

| Alkali Resistance | High (pH 12-14 stable) | High | Moderate (degrades >pH 10) |

| Viscosity Range (mPa·s) | 40,000-200,000 | 50,000-150,000 | 30,000-100,000 |

| Key Strength | Balanced performance/cost | Electrolyte stability | Ultra-smooth finish |

| Limitation | – | Higher cost vs. HPMC | Poor heat/alkali resistance |

Application-Specific Recommendations

▶ 1. Base Choice: VAMCELL® HPMC

-

Optimal For:

-

Universal interior/exterior putties

-

High-temperature regions (≥35°C)

-

Cement/lime-based formulations

-

-

Recommended Grades:

-

VAM-HPMC-60L: Machine application (60,000 mPa·s, fast-dissolving) -

VAM-HPMC-100HV: Hand-trowel & vertical surfaces (100,000 mPa·s, anti-sag)

-

-

Dosage: 0.2-0.4% of total mix weight

▶ 2. Niche Solution: HEMC/MHEC

-

Critical Use Cases:

-

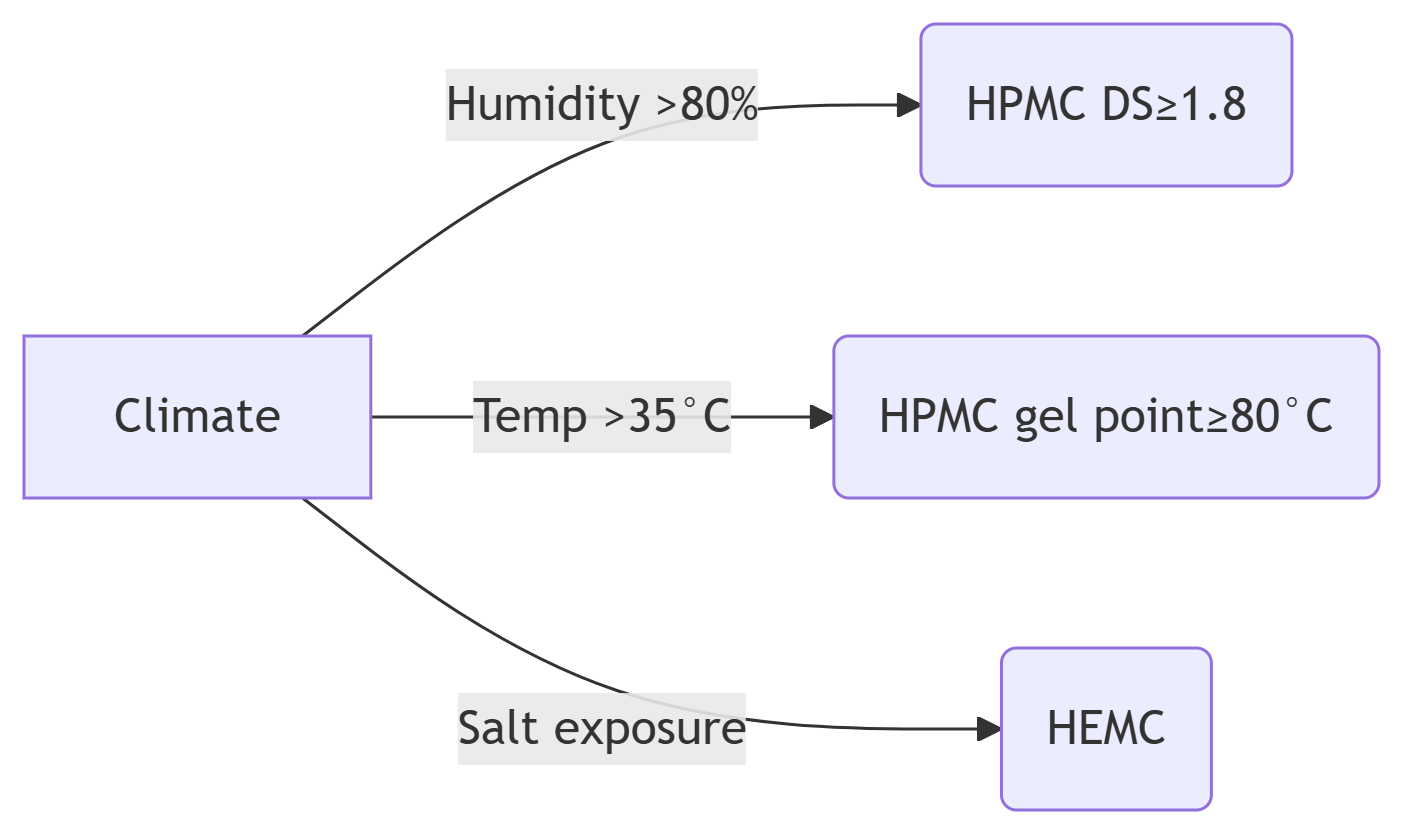

Putties with >3% electrolyte content (e.g., CaCl₂ accelerators)

-

Marine environments or deicing salt exposure

-

Gypsum-cement hybrid systems

-

-

Advantage: Maintains viscosity in high-ionic environments

▶ 3. Specialty Option: HEC

-

Selective Use:

-

Interior decorative putties requiring glass-smooth finish

-

Non-alkaline systems (e.g., clay-based)

-

Low-cost formulations (avoid high-humidity areas)

-

-

Caution: Not recommended for cementitious/exterior applications

4-Step Selection Protocol

-

Analyze Formulation Chemistry

-

Avoid HEC if pH >10 or cement content >15%

-

Choose HEMC when chloride/sulfate ions >5000 ppm

-

-

Define Environmental Demands

-

Match Rheology to Application

-

Machine spray: 40,000-60,000 mPa·s (HPMC/HEMC)

-

Hand application: 80,000-120,000 mPa·s (HPMC)

-

Ultra-thin coats: HEC (30,000 mPa·s)

-

-

Validate Performance

-

Test adhesion (ISO 4624): Target ≥0.7 MPa

-

Check crack resistance (EN 15824): ≤0.3% shrinkage

-

Botai’s Technical Support Advantage

-

Product Tailoring:

-

HPMC substitution adjustment (DS 1.6-2.2) for humidity control

-

Particle size optimization (80-200 mesh) to prevent clumping

-

-

Formulation Services:

-

Free lab testing with customer-specific raw materials

-

Rheology optimization for pumping/spraying systems

-

Case Example: A Guangdong putty manufacturer reduced cracking by 40% switching to:

VAM-HPMC-100HV (0.35%) + GRATARD™ Retarder (0.1%)for high-humidity coastal projects.